Solutions

AI/Ml based intelligent demand forecasting, demand sensing and supply distribution planning solution

Demand Forecasting

The Demand Forecasting module uses a combination of classical statistical forecasting techniques together with modern ML/AI algorithms to generate accurate long-term, medium-term and short- term forecasts. Moreover, the Auto modeling functionality and Hyper Parameter optimization ensures that the system offers you a ‘best-fit’ forecasting model for a given product, location, and planning level combination. Additionally, it empowers citizen demand planners to create accurate demand plans. Furthermore, this is suitable even in lean manufacturing environments, it supports Kanban, a progressive Operations Planning technique that optimizes inventory levels while reducing inventory costs.

- Easy Integration with ERP system like SAP S/4 Hana for Input sales Data

- Auto Model assignment and hyper parameter optimization for empowering citizen demand planners

- Advanced Al/ML algorithms along with classical algorithms for time series forecasting.

- Automatic forecasting generation using scheduled batch jobs.

- User Friendly interactive interface for demand planners to view and modify forecast results

- Simulation and "What-if" analysis for scenerio planning

The Solution enables automatic selection of a 'best fit' forecast model

Advanced AI/ML algorithms in addition to traditional techniques:

- ARIMA

- Multi-Linear Regression

- First and Second - Order

- Holt-Winters Model

- Moving Avg

- Facebook Prophet

- SARIMA

- Croston Model

- Deep AR+

- Weighted Mov Avg

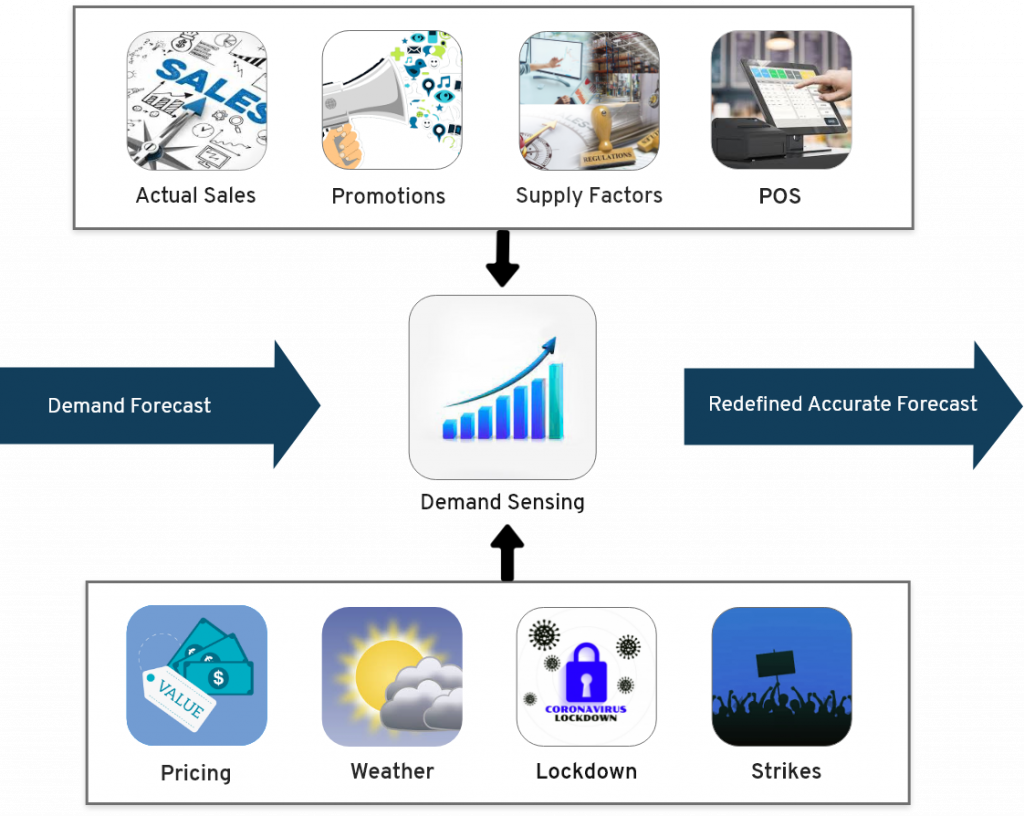

Demand Sensing

The long-term forecast generated by Demand Forecasting is next refined for higher accuracy over the immediate short-term future horizon using various internal & external variables that have a significant impact on sales demand. Specifically, this includes historical data on sales, forecast, and other internal/external variables, such as promotions, price, Point-of-Sales, supply factors, weather events, strikes, lockdowns etc. Moreover, these are used to train an AI / ML model to analyze all events and highlight events that may have a significant impact on sales demand. Therefore, the trained AI/ML models are then used to predict sales demand accurately over the near-immediate future horizon on a real-time basis.

Additionally, traditional methods of demand sensing are so laborious that it is not employed too often as it requires many man hours, and the payback may not be regular enough to warrant the expense. Moreover, the downside is that an event that may have a significant impact may go unnoticed. Hence, our Demand Sensing module eliminates this problem giving the Planner greater accuracy and therefore greater profitability for the company.

The Demand Sensing application handles the complex processes of data preparation for external factor variables before they are used to train the AI / ML models and predictions.

Getting started

Successful implementation of demand sensing needs the right mix of data, technology, people & skills. Furthermore, it’s vital to start on a small but sound base and gradually iterate to expand to more variables and application areas across product categories. The key steps to successful implementation are broadly defined below:

- Collate accurate sales data of past years, forecast, and other internal/external variables

- Identify key internal and external factors that affect sales, ranging from the significant to the not so significant

- Use historical forecasts and actual sales to measure the accuracy of the traditional models used

- Use AI/ML algorithms to build/train models based on historical data

- Use ML/AI models built on these external & internal factors to predict future sales accurately

- Create supply distribution plans based on these accurate forecasts

- Demand forecast is refined for higher accuracy using AI/ML algorithms for immediate short term horizon

- Learns historial forecasting inaccuracies and refines forecast accuracy

- Internal and external factors influencing sales are used for training AI/ML models

-

Data preparation for external factor variables

- Near real-time prediction using the trained AI/ML models for new set of internal and external factors

- User Friendly interface for simulation and 'What-if'analysis to dra insights from data.

Supply Distribution Planning

The refined accurate forecasts from Demand Forecast and Demand Sensing modules are used to generate accurate supply distribution plans throughout the supply chain network. A master-data based user interface allows planners to maintain parameter data for each SKU & location based on which the system generates a distribution plan over a medium-term planning horizon. Moreover, the demand forecast is considered along with current inventory & other receipt elements from ERP systems to create an accurate supply plan. Advanced functionality like Dynamic Safety Stock and Re-Order Inventory Level calculation enables the supply planners to maintain a lean inventory level but ensure a high rate of demand fulfillment without any stock-out situations.

Supply distribution

- Demand Forecast (Medium Horizon) and Demand Sensed Forecast (Short Term Horizon) input to Supply Planning

- Easy integration with ERP system like SAP S/4 Hana for input inventory, PO, STO data.

- Distributed Planning throughout supply chain network

- Dynamic Safety Stock Calculation Re-order level determination for automatic replenishment

- Automated P-Req proposal generation based on current demand, inventory and safety stock requirements

- Output Integration with client ERP systems

- User Friendly interactive interface for demand planners to view and modify forecast results

Data Preparation & Mapping

- Easy integration with a wide variety of ERP systems for master & transaction data

- Data mapping and integration with external source systems

- API-based output data integration with external application systems

- External Factors database for demand sensing

- Data preparation for external and internal variables for use in Demand Sensing