Demand Sensing – Optimising Supply and Demand Mismatch

The goal of supply chain planning is to improve forecast accuracy and optimize inventory costs throughout the supply distribution network. Without proper planning, there is a chance of overstocking leading to high inventory costs or understocking leading to stock out situations causing revenue loss.

When a company produces more than the demand, the stock sits unsold in the

inventory. This increases the inventory holding cost, later leading to waste and

obsolescence costs. When a company produces less than the customer demand, there is a revenue loss and in today’s competitive business environment this might also lead to future revenue losses.

Getting demand forecasting accurate is the key to success in today’s supply chain

planning. There are various reasons why this demand-supply mismatch occurs and

forecasting accuracies drop. Customers’ needs and requirements constantly change, maybe due to:

- Introduction of new technology

- Fast fashion

- Promotional discounts

- Point-of-sales

- Weather

- Strikes

- Lockdowns

For example, when the first wave of the pandemic hit, people minimized their purchases like clothes, cosmetics, etc., thinking they won’t be using these items quite often.

However, there was an exponential rise in the purchase of luxury goods as well as

insurance (health and life). People also bought immunity boosters, comfort foods,

groceries, digital services, and appliances. There was a shift in how people perceived and bought commodities. This leads to uncertainties in aggregate demand. As companies try to fulfill the demand, there is a mismatch between supply and demand.

Traditional classical forecasting methods find it difficult to predict demand accurately in today’s dynamic business environment. Statistical forecast models rely solely on historical sales data and they fail to evaluate the impact of various other variables that impact sales demand. Product manufacturing and distribution must be aligned with supply-demand volume variabilities so that the companies can have accurate demand forecasts, close to the actual sales, preparing them to stock at the right place at the right time in the right quantities.

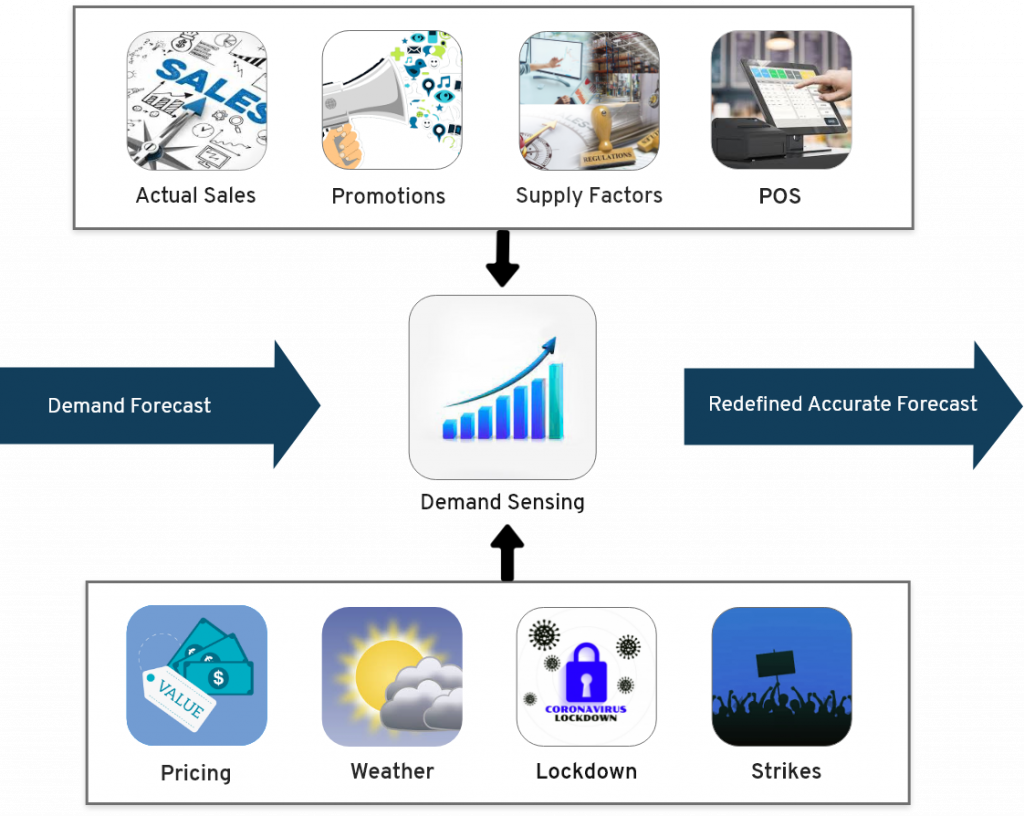

Using modern AI / ML technologies Demand Sensing has now made it possible to

analyze the impact of these variables on sales demand and enable them to predict

demand more accurately. It is fast becoming an indispensable tool in supply chain

planning for accurate demand forecasting. It builds upon the classical traditional

forecasting methods to develop baseline forecasts and then refines these forecasts for higher accuracy by taking into account other variables that impact the sales demand on a near real-time basis. Demand Sensing leads to better demand forecasting accuracy helping organizations to improve customer demand fulfillment, enhance revenues and optimize inventory throughout their distribution network and reduce costs.

Other than optimizing the inventory to meet demands, supply chains can also migrate to a just-in-time inventory management model to boost their responsiveness to consumer’s demands and lower their costs significantly.

Data Required for Demand Sensing

AL/ML-based Demand Sensing tools can make use of a variety of data available to

predict demand more accurately. Such data includes (but not limited to):

- Current Forecast

- Actual Sales data

- Weather

- Demand disruption events like strikes, lockdown, curfew etc.

- Point of Sales

- Supply Factors

- Extreme weather events like floods, cyclones, storms etc.

- Promotions

- Price

The variable may change for different businesses & organizations and any given variable can be modelled in Demand Sensing to analyze the impact on sales demand for greater accuracy.

The list above includes current data, historical data, internal data, and external data. This is exactly why AI/ML-based demand sensing is more accurate than traditional demand sensing. As large volumes of data are analyzed and processed quickly, predictions are specific making it easy for supply chains to make informed business decisions. An important factor to conduct demand sensing accurately is the availability of certain capabilities by supply chains. Let’s learn more about these capabilities.

Capabilities Required by Supply Chains for Demand Sensing

This capability includes data on types of products, shipping dates, locations,

geographical territories, and sell-in channels. This is an important capability as using demand data at this atomic level will help to identify the relevance of outliers, patterns, trends, and short-term spikes.

The demand signal based on demand data also includes noise which needs to be discarded as it has no statistical relevance. Hence, supply chains must be able to model a demand confidence interval that segregates noise from the demand signal and provides insight into the latest data feeds. It is possible with data on complex demand variability.

This capability is required for advanced demand sensing where external variables, such as economic conditions, weather forecasts, market changes, and natural calamities are considered. Data on these variables help supply chains to quickly reposition their inventory to meet unprecedented demand behavior.

High volumes of data related to the number of total products, number and details of each product, number and details of each location in supply and demand management, the demand in each location, the products needed on a daily or weekly basis at each location, and other associated data have to be processed. Supply chains must be capable of scaling large dataset processing.

As the whole idea of the demand sensing tool is to minimize manual effort, supply chains need to be capable of automating the process of executing the demand signals.

Benefits of Demand Sensing

- Greater Demand Forecasting accuracy

- Reduced inventory and higher inventory turnover ratios.

- HIgher customer demand fulfillment leading to increased sales revenues

- Enables citizen demand planners and supply planners.

- Auto-modelling and Hyper parameter

Who Benefits the Most from Demand Sensing?

- Retail/ CPG/ E-commerce

- Distribution

- Manufacturing/Supply chain/ Industrial automotive

- Chemical/ Pharmaceutical

- Food Processing

- Transport/ Logistics

- Natural Resources

Demand Sensing – Need of the Hour

As already discussed, demand sensing is required mandatorily by supply chains to

manage and grow their business. In this dynamic market where most supply chains are opting for digital transformation and an automated process system, traditional methods to sense demand do not work efficiently. To gain a competitive edge and to keep the business running in the current unpredictable times, AI/ML-based demand sensing is the need of the hour.

How aptplan Can Help You

Aptus Data Labs’s AI/ML-based tool “aptplan” helps businesses access accurate

demand sensing and forecasting data to plan their supply accurately. aptplan uses

internal and external data with traditional techniques and advanced technology to train AI/ML models are used to predict accurate sales demand sensing on a real-time basis. It uses NLP technologies to collect a wide variety of unstructured data to convert into a structured format for use. Aptplan delivers highly accurate demand plans for better business decision-making and lower inventory costs. To know more or to request a demo, click on https://www.aptplan.ai/

Tags:

Demand SensingRecent Posts

Search

Lorem ipsum dolor sit amet con sectetur adipicing elit sed do smod tempor incididunt enim minim veniam.

Nicolas Lawson

DesignerLorem ipsum dolor sit amet con sectetur adipicing elit sed do smod tempor incididunt enim minim veniam.

Nicolas Lawson

DesignerLorem ipsum dolor sit amet con sectetur adipicing elit sed do smod tempor incididunt enim minim veniam.

Nicolas Lawson

DesignerCategories

- Coronavirus (2)

- Demand Sensing (2)

- Drawing (3)

- Education (1)

- Nicolas (4)

- Olympiad (2)

- Science (4)